In this blog post, we dissect the practical aspects of EPDM Rubber, also known as Ethylene Propylene Diene Monomer – a material integral to various professional industries. We’ll analyse its properties, compare it with other rubber types, and look into specific grades of EPDM Rubber including Commercial Grade EPDM, WRAS Approved EPDM and Expanded EPDM/Neoprene Closed-Cell Sponge.

Dive into our exploration and learn why EPDM Rubber stands out in terms of its durability, flexibility and cost-effectiveness. We’ll understand its applications in automotive, construction, and electrical industries, showcasing why it’s a preferred choice in numerous scenarios.

If you’re unsure whether EPDM Rubber is suitable for your project and need insights into the distinctions between EPDM Rubber and its counterparts like Neoprene Rubber or Nitrile Rubber, this blog post provides concrete information to guide your decisions.

Properties of EPDM Rubber

EPDM Rubber is a versatile synthetic rubber widely recognised for its exceptional properties. Understanding these key characteristics is crucial for appreciating its widespread use across various industries.

Durability And Resilience:

EPDM Rubber boasts outstanding durability, making it the preferred choice for long-lasting applications. Its resilience allows it to withstand wear and tear, ensuring extended service life in diverse environments.

Flexibility in Varied Temperatures:

One of EPDM Rubber’s standout features is its flexibility across a broad temperature range. Whether facing extreme heat or freezing cold, EPDM maintains its elasticity, making it ideal for applications in challenging climates.

Chemical Resistance:

EPDM Rubber exhibits impressive resistance to a variety of chemicals. This property makes it suitable for applications where exposure to acids, alkalis, and other corrosive substances is a concern.

Ozone and Weathering Resistance:

EPDM Rubber stands strong against ozone and weathering, ensuring it retains its integrity even when exposed to harsh outdoor conditions. This makes it a reliable choice for outdoor applications, such as automotive weatherstripping or roofing.

Excellent Electrical Insulation:

EPDM Rubber is an excellent electrical insulator, making it valuable in applications where electrical resistance is crucial. This property contributes to its use in the production of insulating materials for electrical cables.

Understanding these properties showcases why EPDM Rubber is the preferred material in a multitude of industries. Its unique combination of durability, flexibility and resistance to various environmental factors makes it a reliable and versatile choice for diverse applications.

Applications of EPDM Rubber

EPDM Rubber’s versatility extends far and wide, finding its way into an array of industries due to its remarkable properties. Lets delve into some key applications that showcase the diverse utility of EPDM Rubber.

- Automotive Seals and Hoses – EPDM Rubber’s resistance to heat, weathering, and chemicals make it an ideal choice for manufacturing automotive seals and hoses. It ensures a reliable and durable seal in engines and other critical components.

- Construction Industry Roofing Membranes – The waterproofing capabilities and resilience against weathering of EPDM Rubber make it a top pick for roofing membranes in the construction industry. Its flexibility allows for easy installation and maintenance.

- Electrical Insulation – EPDM Rubbers excellent electrical insulation properties position it as a key material in the production of insulating materials for electrical cables. Its resistance to electrical currents ensures safe and reliable performance.

- HVAC Systems Gaskets and Seals – In heating, ventilation, and air conditioning (HVAC) systems, EPDM rubber is utilised for gaskets and seals. Its ability to maintain flexibility across a wide temperature range ensures a tight seal, enhancing system efficiency.

- Automotive Weatherstripping – EPDM Rubbers durability and resistance to environmental factors make it an excellent material for automotive weatherstripping. It prevents water, air, and noise infiltration, enhancing the comfort and performance of vehicles.

- Industrial Hose Manufacturing – The chemical resistance and flexibility of EPDM Rubber make it a preferred choice for manufacturing industrial hoses. These hoses are used for various applications, including conveying liquids and chemicals.

These applications only scratch the surface of EPDM Rubber’s extensive uses. Its adaptability and reliability contribute to its continued prominence in industries where resilience and performance is paramount.

Advantages of Using EPDM Rubber

When it comes to selecting materials for various applications, EPDM Rubber stands out for its wide range of unique advantages, making it a smart and reliable choice across different industries. Let’s explore some of the key benefits that contribute to the widespread preference for EPDM Rubber:

Cost Effectiveness:

The initial investment in EPDM Rubber may be marginally higher than its elastomeric counterparts, but its exceptional durability and minimal maintenance requirements lead to substantial cost savings over time. This makes it a financially sensible choice for projects with a focus on long term efficiency and budget optimisation.

Low Maintenance Requirements:

The minimal maintenance demands of EPDM Rubber contribute not only to cost-effectiveness but also ensure sustained operational efficiency. With reduced need for frequent interventions, it proves to be a practical solution for applications where uninterrupted functionality is paramount.

Versatility in Applications:

EPDM Rubbers adaptability extends across a diverse range of applications, ranging from automotive components to roofing materials. Its versatility allows it to seamlessly integrate into various professional industries, providing reliable solutions for a multitude of uses. This adaptability makes EPDM a versatile and dependable choice for projects.

Resistance to Chemicals and Environmental Factors:

The robust resistance to chemicals and environmental factors sets EPDM Rubber apart in challenging conditions. Whether exposed to corrosive substances or enduring harsh outdoor elements, EPDM Rubber maintains its integrity, ensuring unwavering reliability. This resistance makes it a preferred material for applications where environmental resilience is critical, such as industrial settings or outdoor installations.

Comparing EPDM with Other Rubber Types

Choosing the right material is crucial for the success of various applications, and understanding how EPDM Rubber compares to other commonly used elastomers is essential. Let’s explore the comparisons between EPDM Rubber and Neoprene Rubber, Nitrile Rubber, Viton Rubber, Natural Rubber and Silicone Rubber.

- EPDM Rubber vs. Neoprene Rubber – While both offer good weather resistance properties, EPDM Rubber excels in UV and ozone resistance. Neoprene is known for its oil resistance however, making it suitable for different applications, including automotive seals and gaskets.

- EPDM Rubber vs. Nitrile Rubber – EPDM Rubber outshines in weather resistance and UV stability, whereas Nitrile Rubber offers superior oil and fuel resistance properties. Applications in automotive and aerospace fuel systems typically favour Nitrile Rubber, while EPDM Rubber finds use in roofing and outdoor applications.

- EPDM Rubber vs. Viton Rubber – Viton Rubber offers superior chemical resistance, especially in harsh environments. However, EPDM Rubber is significantly more cost-effective and is more versatile across a wide range of applications.

- EPDM Rubber vs. Natural Rubber – Natural Rubber is renowned for its elasticity and versatility, but lacks UV and weather resistance. EPDM Rubber, on the other hand, excels in UV stability, making it the go-to choice for outdoor applications.

- EPDM Rubber vs. Silicone Rubber – EPDM is more cost-effective and offers unique properties, however Silicone excels in high temperature resistance, making it the preferred option for applications involving extreme heat, such as in cooking or baking equipment.

Grades of EPDM Rubber

EPDM Rubber comes in various grades, each designed to meet specific requirements across different applications. Understanding these distinctions between grades is crucial for selecting the right EPDM rubber for your intended purpose. Let’s delve into three notable grades: Commercial Grade EPDM Rubber, WRAS Approved EPDM Rubber and Expanded EPDM/Neoprene Closed-Cell Sponge Rubber.

Commercial Grade (CQ) EPDM Rubber

Commercial Grade EPDM Rubber serves as the foundational choice for many different professional industry applications. Recognised for its combination of durability, flexibility and cost-effectiveness, it’s often the go-to elastomer for projects requiring a reliable, all-purpose material.

CQ Grade EPDM Rubber is ideal for scenarios where high-performance specifications aren’t paramount, the material excels in common applications like roofing membranes, gaskets and straightforward weatherstripping. Its balanced properties make it an optimal choice for various general purpose applications.

WRAS Approved EPDM Rubber:

WRAS Approved EPDM standards with its specialised certification involving usage with portable water for human consumption. Adhering strictly to the Water Regulations Advisory Scheme (WRAS), it ensures the highest standards of safety and quality in water-related contexts.

WRAS APproved EPDM is crucial in water and plumbing systems, where maintaining water quality and adhering to stringent regulatory standards is non-negotiable. ITs also the material of choice for applications demanding strict adherence to water safety protocols, including applications where water intended for human consumption is involved.

Expanded EPDM/Neoprene Closed-Cell Sponge Rubber:

Combining EPDM with Neoprene in a closed-cell structure, this grade elevates its insulation properties. The closed cell structure of the Expanded EPDM/Neoprene sponge prevents water absorption, making it particularly valuable in applications where moisture resistance is paramount.

Expanded EPDM/Neoprene is frequently used for applications requiring both effective insulation and resilience against environmental element.s For example in HVAC systems and outdoor gasketing, the material excels in scenarios that demand robust protection against moisture and external stresses.

Where to Buy EPDM Rubber

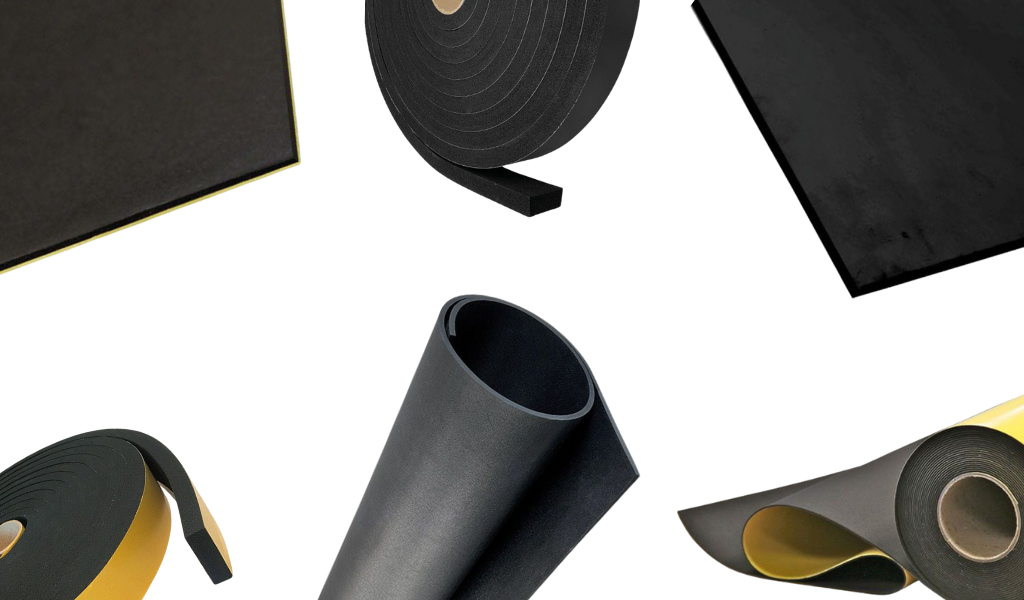

If you’re looking for EPDM Rubber and need a reliable supplier, look no further. At Delta Rubber Limited we specialise in offering EPDM Rubber in various forms to meet a diverse range of needs. From rubber sheets, rubber rolls, cut rubber strips, rubber gaskets, washers, seals and extrusions, we have you covered.

Our off-the-shelf range includes Commercial Grade EPDM Rubber sheets, available in sizes ranging from 1 metre to a full 10 metre roll, 1.4 metres wide, and in various thicknesses. We also offer CQ grade EPDM Rubber cut strip, sold in 5 metre lengths with customisable width options from 10mm to 500mm and various thickness.

Expanded EPDM/Neoprene Closed-Cell sponge sheet is also available in lengths of 1 metre to a full 10 metre roll, 1 metre wide and a variety of thicknesses. This material can also be purchased in cut strip form, sold in 10 metre lengths, with a range of width and thickness options. Expanded EPDM/Neoprene Sponge is available with self-adhesive backing.

Our in-stock range of WRAS Approved EPDM Rubber is available in 3 thicknesses; 1.5mm, 3mm and 6mm thick, widths from 1.4m to 1.62m and sold in lengths of 1 metre to a full 10 metre roll (other size options available upon request).

If your project demands a bespoke component to be manufactured from EPDM, please don’t hesitate to contact us for assistance. With access to cutting-edge manufacturing equipment, an impressive 110 years of experience and an unrivalled dedication to technical projects, we are the number of trusted suppliers for bespoke rubber products and components in the UK.

Whether you need a bespoke EPDM gasket manufactured, prototype seal developed or a large volume order of weatherstrip, we guarantee quality and offer tailored solutions for your application. Contact us today for information and learn how Delta Rubber Limited can elevate your next project.